Millet Mill Machine

Brand Golden Grain

Pinagmulan ng produkto Tsina

Oras ng paghatid 15 Araw ng Paggawa

Kapote ng suplay 100sets/buwan

1. Ang kagamitan sa pagpoproseso ng millet ay may mga pakinabang ng awtomatikong operasyon, na nakakatipid sa gastos sa paggawa.

2.Mataas na kahusayan sa produksyon at mababang pamumuhunan.

3. Ang kagamitan sa pagproseso ng millet ay may compact na istraktura at maliit na lugar sa sahig.

4. Ang mga kagamitan sa pagproseso ng millet ay maaaring i-order ayon sa mga kinakailangan ng mga customer.

Millet Processing Machine

Prodcut introduction of Millet Processing Machine

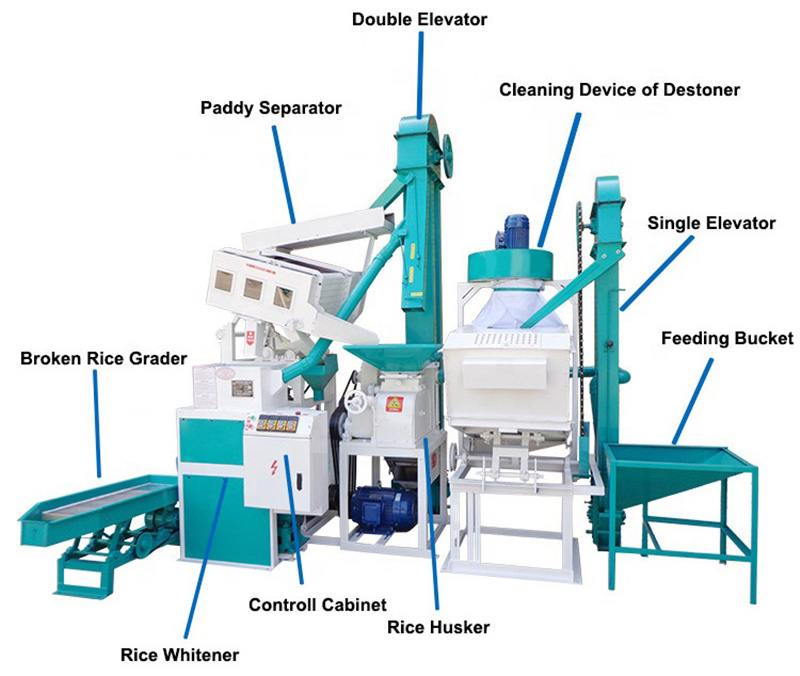

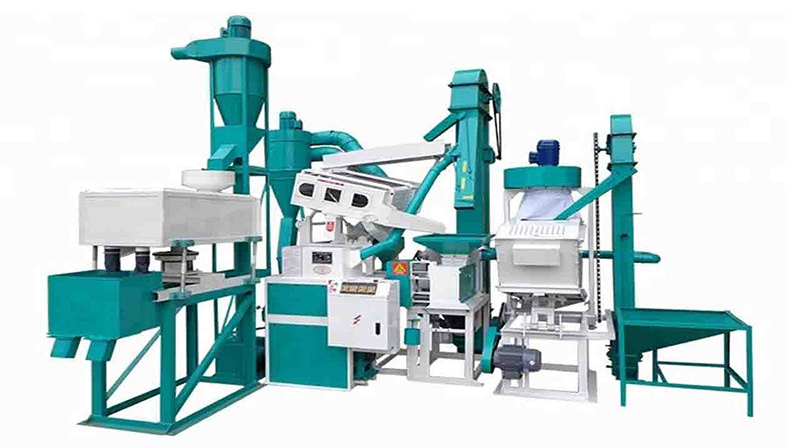

Millet processing machine refers to the millet processing plant, which consists of the following sections: millet cleaning, hulling, husk and millet separation, milling (peeling, whitening, polishing), color sorting and packaging.

Millet Milling Machine Technology Flow

Millet cleaning---stoner---hulling mill---grading sieve---peeling off------polishing---grading---color sorting---packing

Bucket Elevator of millet milling machine is mainly used to transport millet in complete processing line.

Vibrating screen of millet processing machine is specially used for separating the impurities from millet.

After cleaning, millet will be transported into stone remover machine to separate the stone from the millet.

Next, the millet into the hulling machine to remove the shell.It can separate the shell from the paddy husk mixture through the suction effect.

The millet that has removed the shell will be into the iron polishing machine.The machine is mainly used for cleaning the millet to make them look brightly. It is one of the key processing millet.

Suction Separator will separate the low gravity impurities(such as hull, dust etc.) from the millet.

Out from the suction separator ,the millet into the color sorter to get more high quality millet, white millet and break millet will be passed.

Finally, high quality millet will be packed through the Automatic Packaging Scales.

Product parameters of millet processing machine

| Machine List | Power(Kw) | Capacity Output (kg/h) | |

| 1. Single Elevator | 0.75KW | 21 .37KW | 500-700 kg/h |

| 2. Drum cleaner and destoner | 0.75+1.5KW | ||

| 3. Paddy separator Machine (5 layers) | 0.75KW*2 | ||

| 4. Double Elevator | |||

| 5. Rice Husker (6') | 5.5KW | ||

| 6. Rice whitener | 11KW | ||

| 7. Rice Sieve | 0.37KW | ||

| 8. Control cabinet | |||

| Installation Size: 3500*2600* 3000 mm | |||

Product features and application of millet grinding machine

Millet grinding machine---Automatic operation, saving labor cost.

Millet milling machine---High production efficiency and low investment.

Millet grinding machine---The equipment has compact structure and small floor area.

Packing&Delivery of millet milling machine

Packaging Details

1. We will pack all single machine of millet milling machine with the plastic film.

2.Fix the millet grinding machine on the container for the safety of long-time transportation of goods.

3.Some special unit of millet processing machine will be putted into the box to avoid any damage or missing.

4.Small parts of millet milling machine will be putted into the bags, boxes or make special packaging.

5. According to customer requirements, each product of millet grinding machine is labeled with name and quantity.

Port:Dalian,China

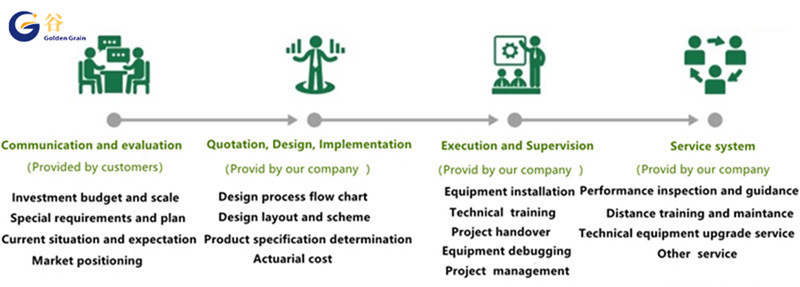

Our cooperation with foreign clients.

If you have any questions, welcome to contact us!

Company information

Liaoning Golden Grain Grain and Oil Machinery Co., Ltd(Formerly known as Zhengshuanghuan General Equipment Manufacturing Co.,Ltd)was established on August 30,1992 in Shenyang, China.

Our company has nearly 30 years professional experience in manufacturing Grain Machinery,the main products includes :Maize Milling Machine,Rice Milling Machine,Millet grinding machine,Wheat Flour Milling Machine,Sorghum Milling Machine,Millet Milling Machine and Oil Refining Machine.

Factory covers an area of 20000 square meters, 6000squrare meters office building area,owns high quality standard heavy industrial production workshops.

Employees includes medium and senior professional management personnel, engineering technical personnel and professional foreign trade team sales staff.

We design products according to customers’ specific requirements with carefully installation and technical training. Products have been exported to many countries such as:Russia,North Korea. Viet Nam, Nigeria, South Africa, and Southeast Asia. We are willing continue to expand our business around the world.